Case Study: Cuajone Expansion, Peru

Owner: Southern Peru Copper Corporation

Contractor: SSK Ingenieria y Construction

Location: Cuajone, Peru

Located in the rugged Peruvian Andes, the Cuajone mine is the largest single copper mine and smelter complex ever built. The 4,144-square-kilometer mining triangle begins high in the Andes with a water supply at Lake Suche and ends with a smelter on the Southern Pacific coast.

Project highlights:

120m structure for copper ore

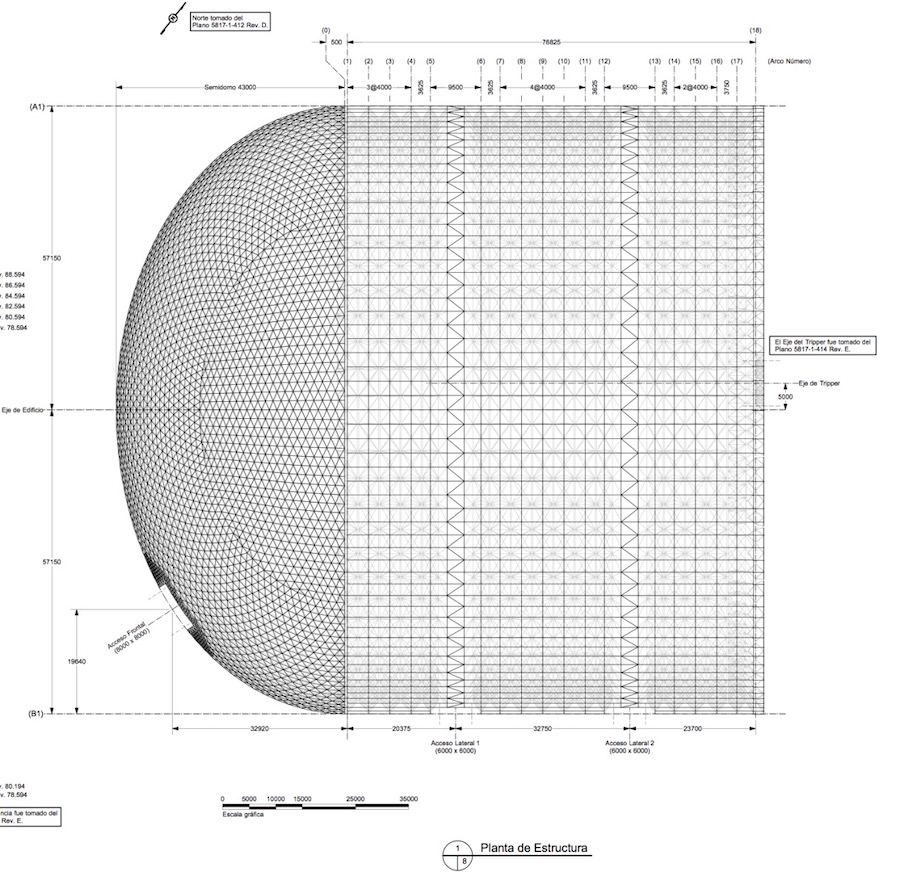

Includes three structure types - arch vault, semi-dome, and end wall

Built concurrently during stockpile operation

Covering copper ore was part of Southern Peru’s overall initiative to reduce operating and maintenance costs as well as the environmental impact of the Cuajone mine. This mine has enormous copper reserves with production dating back to 1976.

The project involved the design of a super-structure that incorporated three structure types - an arch vault, semi-dome, and end wall. Installation of this structure completed in Summer 2016.

Southern Peru Copper Corporation drafted a performance specification that included all dimensional and loading requirements for the stockpile cover at this existing mine site.

The structure would have to allow two lateral access points of up to 6x6m for medium vehicles and a frontal access of up to 8x8m for a 200 MT crane. Ten windows were also incorporated for ventilation.

Special foundations support this super-structure in both plan and elevation. The semi-dome sits upon an elliptically shaped foundation and the end wall sits on a retaining wall with five different levels. Embedded plates anchor the structure. The structure is made of galvanized steel tubular bars joined by high-strength cylindrical aluminum connectors. Not only lightweight, galvanized steel provides corrosion resistance for years of worry-free storage with minimal maintenance.

The vault section was formed by stitching together a total of 17 arches for the main body, with the addition of a semi-dome at one end and a vertical wall to enclose the other end.

Scaffolds were used by the local crew to assemble the arch vault sections on the ground. The depth of each arch was 4.5m with a width of 4m.

For the arch vault and end wall sections, the "lift in place" method of construction was used. Sections were assembled at ground level and lifted into place with a standard construction crane. With most assembly done at ground level, mine operations did not have to stop inside.

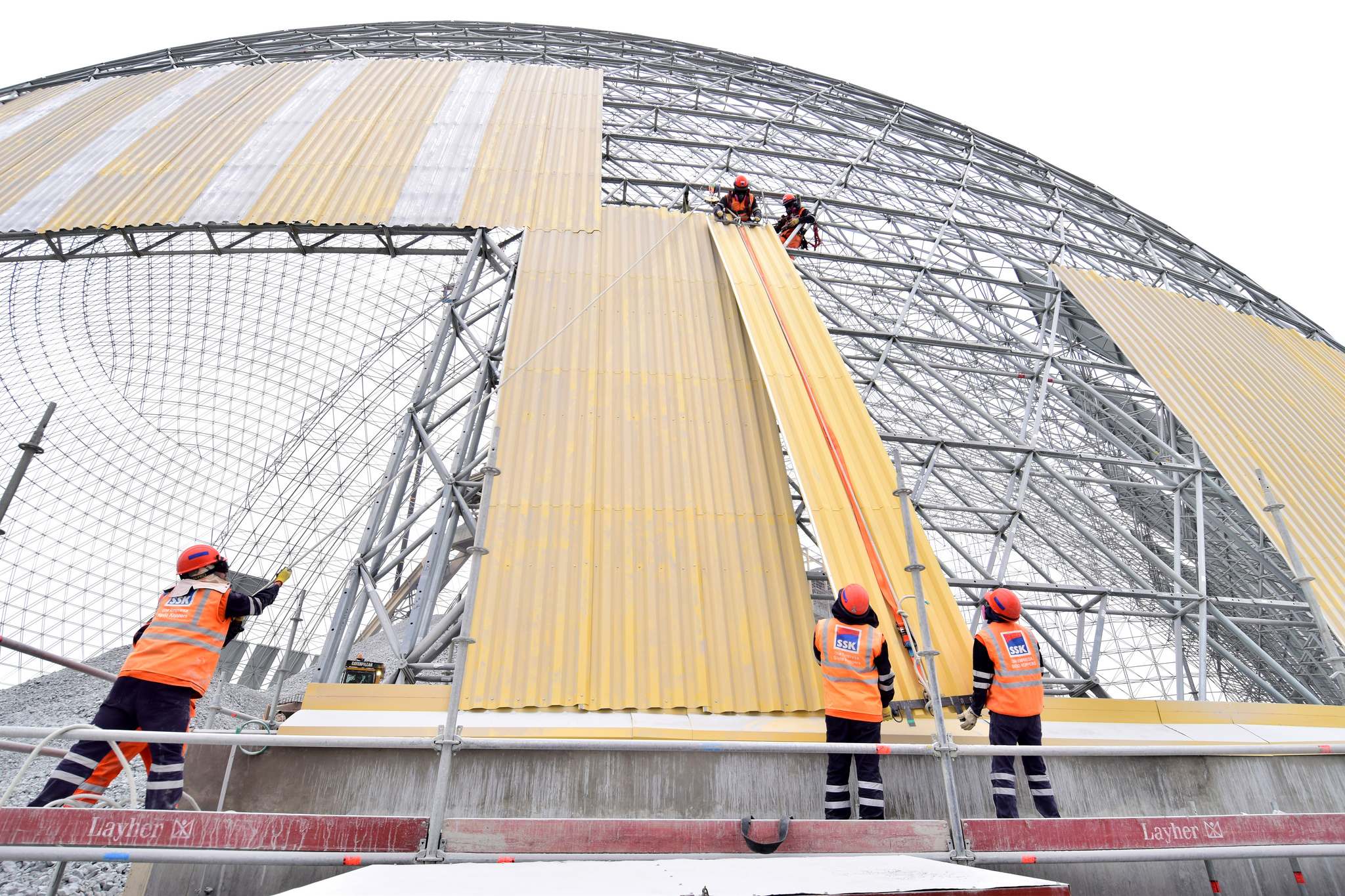

For the semi-dome end, workers assembled one ring at a time, from the perimeter ring to the dome's apex. This self-supporting construction technique is an extremely practical assembly method that requires no ground level equipment to interfere with operations.

Cladding, made of galvanized and painted corrugated steel panels cover 90% of the surface areas. All panels are the same gauge, one width and different lengths. Translucent acrylic panels in a matching profile cover the remaining surface area to allow natural light into the structure. Additional cladding components include ridge caps, rain gutters and skirt flashings.

Results

Cuajone’s ambitious expansion project presented epic challenges in a tough environment. At 3500m above sea level, working conditions were strenuous and access was difficult at best.

Today, the Cuajone mine is one of the largest and most efficient base metal mine complexes in the world. Geometrica’s hybrid dome helps mitigate dust and also helps protect the mine’s bottom line. Fighting off wind and rain safeguards inventory from contaminants, erosion, and deterioration. The material is kept dry, ready for immediate handling and it’s not depleted or contaminated.