Power Generation

Electric power, solid fuel, waste management, sustainable energy... Geometrica is a global expert in long span applications for energy generation and power plants. In a "look back" at power generation projects, we recall storage structures in Taiwan, the UK, Qatar and Jacksonville, Florida. These applications help make the storage of coal, petcoke, biomass, compost and recyclable products a reality.

Tai Power's Four Massive Silos

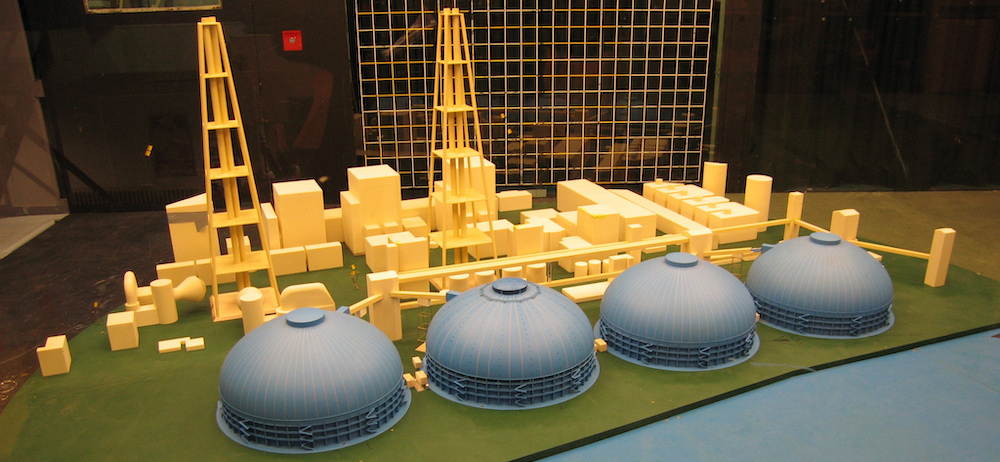

Tai Power, Taiwan’s state-owned Energy Company, needed a fuel storage solution at the Hsin-Ta Fossil Power Station in Kaohsiung Hsien. As a part of their expansion plans, they wanted to store fuel material under cover. The challenge was to design silos that could resist corrosive saltwater spray and typhoon winds. Gibsin Engineers LTD, a specialist company hired by TaiPower, determined that four long span concrete silos with metal dome covers would be required. Gibsin Engineers specified galvanized steel for the structure and aluminum for the cladding.

Several proponents from around the world bid for the turnkey installation of the dome covers. The team consisting of Geometrica, Inc., Triumstar International Co. Ltd. and Chien Yang Construction and Engineering Co. Ltd. (both from Taipei), were awarded the job. The long span solution consisted of four 126m diameter concrete silos with internal automated stacker/ reclaimer system. Each unit would store 180,000 t of coal in a live pile for a total of 720,000 t. Geometrica handled engineering, manufacturing and technical assistance during installation, and construction on site, which began in July, 2006.

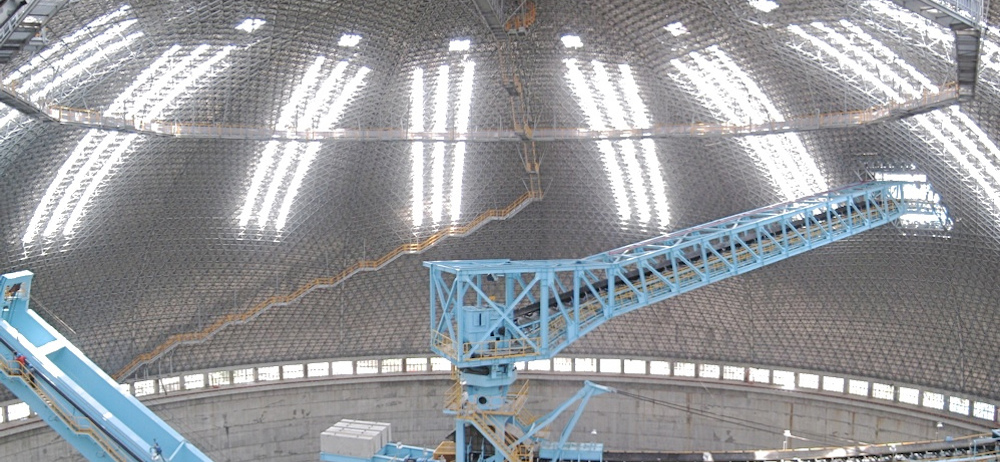

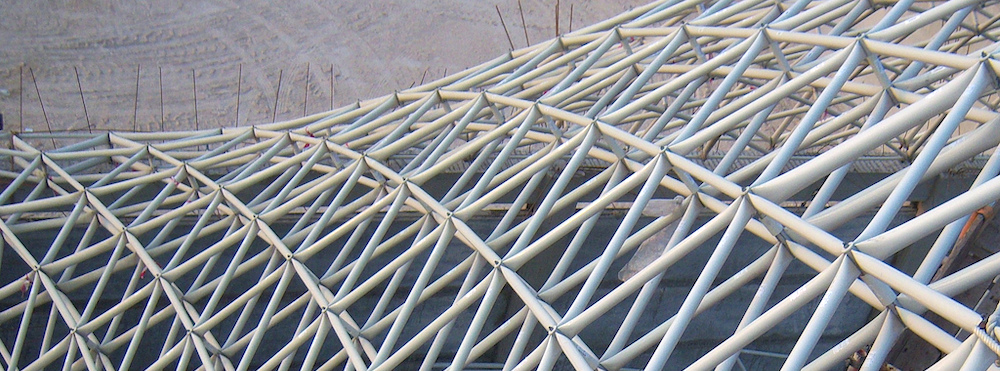

The domes were assembled using the “perimeter-in” method of construction: the first nodes and tubes were laid on the supporting concrete wall. Each 3 to 5 tubes were joined to one node forming a “spider.” Each spider was then raised to the work front and tapped into place, creating rings around the base that grew one on top of the other until the whole skeleton was formed. Coordination with other trades was easy, as the area under the dome was free of obstacles. Neither scaffolding nor other special equipment were required, and the project was completed with a perfect safety record.

Turnover of the domes and testing of the first silo started in October 2007, approximately 16 months after start of construction. Today the Taiwan Power Company produces electric power in a clean and safe environment for surrounding communities.

Best Designed Project in the United Kingdom

o longer a dirty word, “waste” is processed as a renewable and clean energy source in municipalities worldwide. Nearly everyone is on-board with recycling, re-using, re-purposing and reclaiming disposable items previously doomed to landfills. Communities are making a shift to sustainable energy sources through the processing of plant and animal matter, as well.

Biomass has become more manageable — and more useful — through biopower technology. The delivery, processing and storage of biomass has certainly evolved according to Francisco Castaño, president of Geometrica. He notes that aesthetics and sustainability are a double-edged positive that has entire nations looking at power sources through a new lens. Biomass can be processed, stored and distributed beneath long spans of thoughtfully designed waste management infrastructure. These types of efficient domes are exemplified in the Marchwood facility, a prime example of biomass processing and storage in the UK.

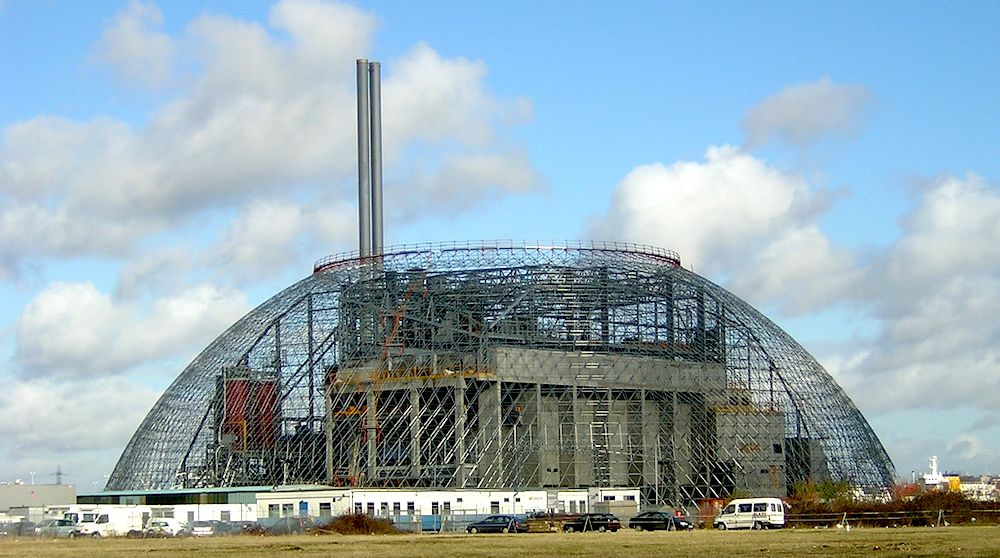

Biomass is a natural material which is broken down in the facility much like it is broken down in nature. Beneath the Marchwood “Silver Dome,” a host of biochemical conversions take place as a key to energy complete power plant that spans 110m and supplies electricity to more than 22,600 homes.

The energy recovery project proves that social value and careful design can elevate even a waste treatment facility into a thing of beauty. The dome, designed by renowned French architect Jeanrobert Mazaud, now conceals and beautifies an incinerator facility, with only the twin chimneys stretching upward through the elegantly curved roof. The original concept, if built with conventional hot-rolled steel, called for more than 1,000 tons of superstructure. The Geometrica dome, using galvanized structural tubing joined with high-strength aluminum hubs, weighs less than 300 tons.

The Marchwood Silver Dome has become a stunning shoreside icon in the United Kingdom community of Southampton, Hampshire, which also plays host to the two great ocean liners, the Queen Elizabeth 2 and the Queen Mary. The facility is a leading example of environmental practice and quality handling of biomass, and won the 2009 Best Designed Project Award by Partnerships Bulletin (formerly Public:Private Awards). But the real prize is that nearby families are now warmed by newly generated power as an industrial jewel graces Southampton Water.

The First of its Kind in the Middle East

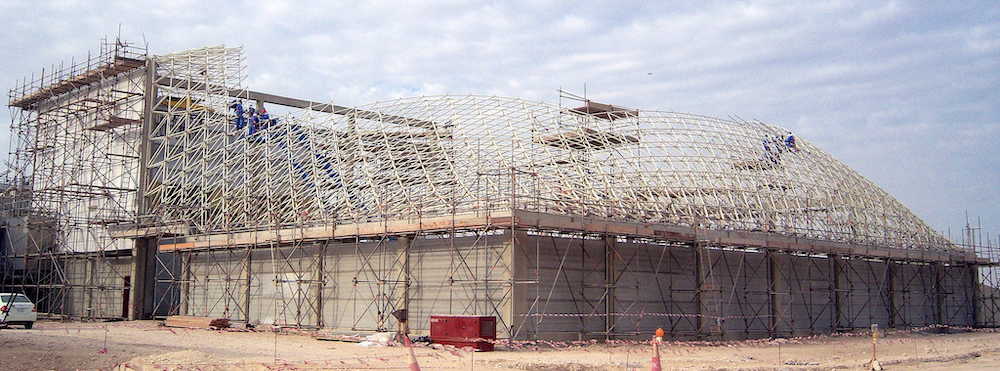

Word of mouth brought Geometrica into another waste-to-energy challenge. Marchwood Silver Dome contractors who had worked side by side with Geometrica shared news of a project in the Middle East — the Qatar Domestic Solid Waste Management Center (DSWMC). It was proving difficult to find a firm that could match the developer's vision of a distinctively designed facility. Because Geometrica designs some of the world’s largest free span domes, this technology became a solution for a challenging architectural feat.

The plans included installation of state-of-the-art systems for separation and recovery of resources and energy from waste, including sorting, mechanical and organic recycling, and waste-to-energy composting. The goal? To have these processes work together synergistically, complementing and feeding off one another to support increased energy and material recovery from households, commercial establishments and the construction industry. The side benefit included a surplus of multiple dozens of megawatts to the national grid.

Early in the construction process, Keppels Seghers, a Singaporean engineering firm, was contracted to design, build and operate the DSWMC’s Green Waste Storage Composting Plant. They sought a roof structure which processes yard and garden waste, tree cuttings, as well as food and kitchen products such as expired vegetables or peels. The material is subsequently shredded, screened and stored inside the Green Waste Storage facility. Grab-cranes then feed the material into anaerobic digesters which further break down the waste and produce biogas, which is eventually translated into a form of power generation.

To house the green waste breakdown process, Keppels Seghers required a structure that could span the large, open space of the building without internal support columns to interrupt the flow of materials and waste. Initially, Keppels Seghers designed the structure as a large steel framed roof with trusses. However, after considering the advantages of the Geometrica system, Keppels Segher opted for Freedome. “We were already aware of Geometrica's systems,” said Geoffrey Piggott, the Keppels Seghers director of the Qatar facility. “But they visited us, and gave us an impressive proposal that was aesthetically attractive, cost competitive and had schedule advantages to us, as well.”

The Qatar Freedome is rectangular in shape and sits on a concrete perimeter that varies in elevation. The dome is almost 20 meters tall above its support wall, is clad in with 3,384 panels of painted steel, and covers 1,923 square meters of area required to house the Green Waste storage and its various sorting and shredding machinery. According to the Qatar Green Building Council Solid Waste Interest Group, the DSWMC is the largest composting plant in the world, and Geometrica’s unique structural system of offered the ideal cover for it.

The DSWMC first began operation near Mesaieed, Qatar, in October 2011. The facility treats and processes domestic solid waste for the whole of Qatar, recycling select materials and using organic waste and biomass to generate various forms of energy. More than 95% of the waste is reclaimed or converted into energy, with less than 5% of the materials entering the facility diverted to a landfill. The facility is capable of treating up to 2,300 tons of domestic solid waste per day, and incinerates approximately 1,000 tons of other waste.

Powering Up in Florida

In a noontime ceremony that brought new meaning to the term "power lunch," government leaders, U.S. DOE officials, industry professionals, and the editors of POWER magazine declared the nation's newest clean-coal powerplant fully operational. Bob Schweiger, POWER's consulting editor, was on hand in Jacksonville, FL to present the magazine's 2002 Powerplant Award to JEA's Northside generating station.

Geometrica provided two dome structures each measuring 122m for the JEA project, which received the prestigious award for outstanding achievement in the development of a successful repowering strategy. The challenge was to convert two aging, underutilized oil/gas-fired steam plants to solid fuels by utilizing circulating fluidized-bed technology. This effort increased efficiency while reducing both emissions and the cost of electricity (see POWER, September 2002, p. 20).

Safety features were an inherent part of the award winning design and mitigation strategy. "Domes can be manufactured from steel or aluminum," says Castano. "Steel is less expensive, but aluminum is better for locations where there is high corrosivity, such as near oceans." Aluminum helps minimize the opportunity for coal dust to settle on parts of the structures, which reduces the combustible atmosphere and potential for explosions and fires related to coal and coal dust. The barrier-free interiors of both domes has minimal surfaces for dust to accumulate, and its ventilation system reduces the chance for methane build up. "Ventilation should be provided at the apex to take advantage of the chimney effect," says Castano. The structure should also be vented at the perimeter to reduce damage to the structure due to blast overpressures.

Into the Future

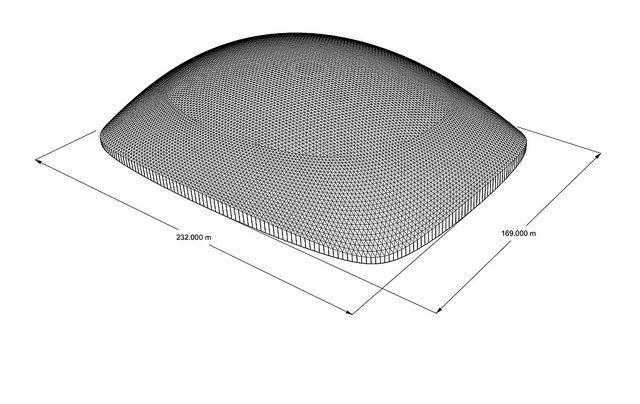

Existing power plants around the world store fuel in open-air stockpiles. As communities become more environmentally conscious, they are demanding that these stockpiles be covered. Up to now, such covers were beyond the practical reach of most structural systems. But not anymore. Geometrica's Freedome® technology allows coverage of free-form areas of 200 to 300m of clear span.

Often parallel coal stockpiles share stacking or reclaiming equipment, making it impossible to add supports at the middle of the stockyard. Geometrica can design domes that cover a near-rectangular plan area very efficiently, and achieve spans of well over 100m.

Plan View: Freedome® for twin stockpiles

Perspective View: Freedome® for twin stockpiles

In other cases, the stockpiles are formed with slewing conveyors and front-end loaders, resulting in stockyards of odd-shape and very large areas. These can also be covered with Freedome®.

Plan View: Freedome® for irregular stockpile

Perspective View: Freedome® for irregular stockpile

Freedomes are a reality. Geometrica has built dozens of large, column-free domes over free-form areas. As a recognized leader in the field, Geometrica's dome installations serve cement plants, mines, power plants, fertilizer plants, ports and other bulk handling industries in over 30 countries.

The question is, "What can Geometrica do for you?" Contact us for industrial and bulk storage solutions suitable for any terrain or climate by filling our inquiry form.