Resisting Corrosion in Veracruz

It is a lovely port city. As Mexico's traditional and colorful gateway, Veracruz welcomes trade and tourists with friendship and warmth. But it is not as welcoming to metal buildings. Veracruz is a notoriously corrosive location. Host to oil processing and refining complexes, the city has a tropical, industrial, humid, marine, salt-sprayed, "ISO 9223-C5 very high corrosivity" atmosphere. Corrosion there feasts on metal faster than tourists on tacos. And Veracruz also suffers from hurricanes bearing in from the Gulf of Mexico every few years.

Grupo CICE, a company trading in fertilizers and other commodities, needed a long-span storage building at the port of Veracruz. As if the local harsh environment was not a sufficient challenge, the building was to store 15,000 tons of urea. Urea is a fertilizer. When dry and in pellets, it is not so aggressive. But its component and by-product, ammonium carbamate, can form from the aggregate, and it is extremely corrosive to metals in humid conditions. Thus, of the very few locations in the world that may be more corrosive than the port of Veracruz, one would be right inside the new Grupo CICE building.

CICE contacted Geometrica.

A cost-effective solution

CICE needed a building to span 52m by 120m without intermediate columns that would resist Veracruz's tropical hurricanes. For this span, metal is the way to go. But how to protect a metal structure from corrosion? Painted steel buildings do not last long in Veracruz. Stainless steel was prohibitively expensive.

Aluminum structures were a possibility. Aluminum resists corrosion by forming a thin layer of hard aluminum oxide that arrests further rust. As long as the pH in the environment is not too high or too low, then an aluminum structure can withstand attack from chlorine in salt spray as well as from pollution particles in the air. However, inside this building, aluminum was not ideal. Urea and its components, in the presence of humidity, can easily create off-neutral pH values that attack aluminum. CICE asked Geometrica for a solution what would resist corrosion both inside and out, cover the required long span and resist hurricane winds, all without blowing the budget.

Exoskeleton, plastic skin

Freedome® technology includes a variety of options. Structures and cladding may be made of steel or aluminum. Cladding may also be made of acrylic, glass, fiber-reinforced plastic, polycarbonate or a combination of these. And cladding may be applied inside or outside the structure, or both.

For this project, Geometrica proposed using AA 6061-T6 aluminum alloy for the structure and FRP internal cladding. The proposed alloy is strong and very resistant to atmospheric corrosion, so it could be left exposed to Veracruz's industrial-marine environment. And the internal cladding would protect the structure from the chemicals in the building.

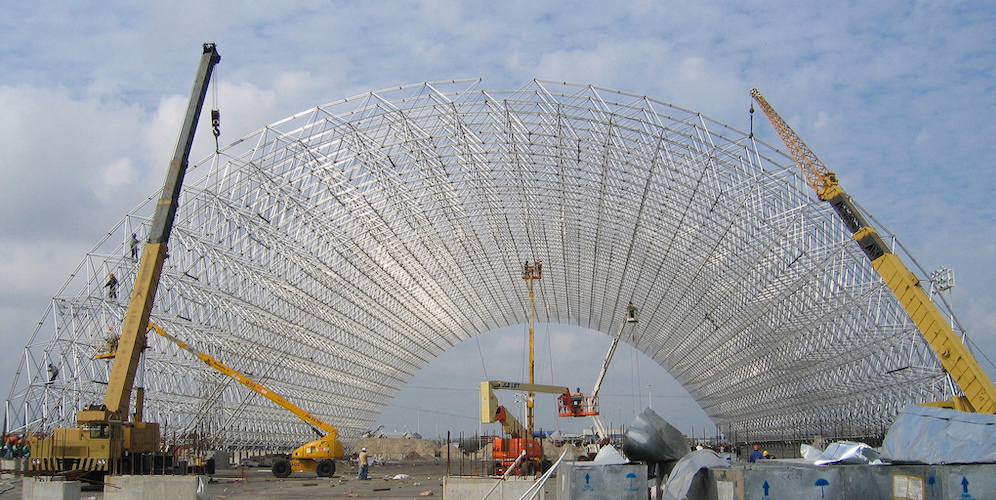

Trusses of varying depth would make up a barrel-vault. To provide increased resistance, the trusses would be deepest where hurricane-induced bending moments were highest. The structure also had to provide sufficient support for the relatively-flexible plastic cladding, so additional bracing members were extended to support purlins on the bottom chord.

Quick construction

No welding or special tools are required to assemble Geometrica Freedomes. These structures can be assembled in a short amount of time by local personnel who are trained on site. This has the additional benefit of bolstering regional economies. In the CICE building, individual truss-arches were assembled on the ground and lifted into place with cranes. Cladding was installed from manlifts inside the structure. The process required a minimum of space, time and equipment and permitted other subcontractors to work side-by-side on site.

Fill-er up

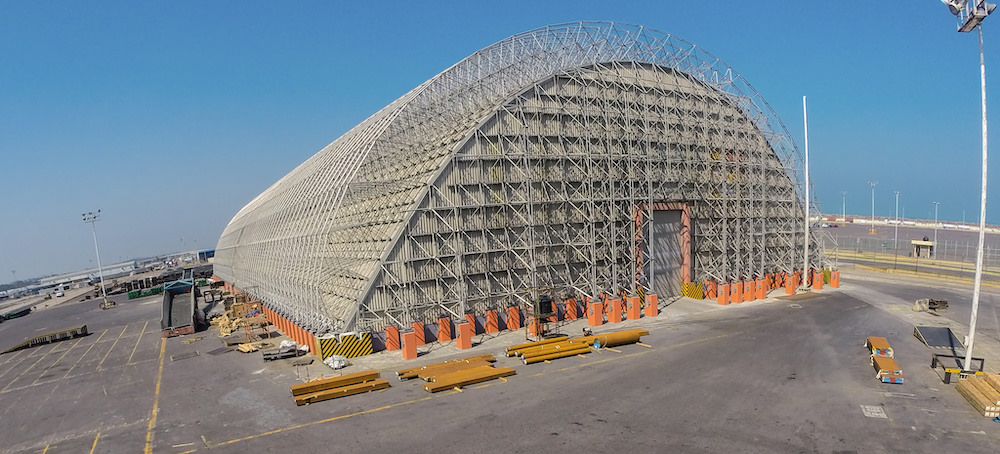

The building was put into service immediately after completion. Now the aluminum itself resists atmospheric attack, while the plastic skin keeps the stored urea from the metal. Corrosion must find something else to feed upon. So, if you are ever at the port of Veracruz, it is you that will do all the feasting. Your eyes, on CICE's beautiful exoskeleton, and your tummy on those delicious tacos.

Global Leader in Dome Design

Geometrica covers can be constructed while the stockpile is in operation, with little or no downtime. In fact, stockpiles of all types benefit from Freedome® technology, which allows full use of soaring infrastructure without the hindrance of columns. Unobstructed space allows the free flow equipment, personnel and inventories for the best possible materials-handling processes. These benefits make Geometrica the ideal dome supplier for your next storage project. For more information fill our inquiry form.